Plasma cutting method compared to other cutting methods

Plasma cutting method has a wide application, not like flame cutting, plasma cutting also can cut stainless steel, aluminum, brass, etc. In recent years, plasma cutting method has become more and more popular in ship building, railway, steel structure, pipeline construction, automobile and other industry.

Plasma cutters work by sending an electric arc through a gas that is passing through a constricted opening. The gas can be shop air, nitrogen, argon, oxygen. etc. This elevates the temperature of the gas to the point that it enters a 4th state of matter. We all are familiar with the first three: i.e., solid, liquid, and gas. Scientists call this additional state plasma. As the metal being cut is part of the circuit, the electrical conductivity of the plasma causes the arc to transfer to the work.

This is some feature of plasma cutting method:

1). Cutting speed is high, up to 10 times higher than oxygen cutting.

2). Cutting surface quality is good while the kerf is small compared to flame cutting.

3). Excellent performance in small and medium sized thickness of mild steel.

4). The heat affected area is small.

5). Operation cost is moderate compared to laser cutting.

plasma cutting machine

Here is a list of plasma cutting method compare to other cutting method:

| General advantages and disadvantages of each of the cutting methods |

|

Process

|

Advantages |

Disadvantages

|

|

Flame

(suitable for construction steel only)

|

- For middle and bigger thicknesses of the material.

- Economical use of multiple burners.

- Small investment and operating costs.

- With up to 3 torch in one kit.

|

- Poor cutting below 5 mm.

- Material curvature in the lower range of sheet metal; straightening necessary.

- High heat input, a large heat affected zone.

- Small dimensional stability for repetitive cuts due to the heat influence.

- Small cutting speed.

|

|

Plasma

|

- Operation of one or more burners according to the series.

- Cutting of all electrically conductive materials.

- Without alternatives for cutting high-alloy steel and aluminum materials in medium and larger thickness.

- Excellent performance in small and medium -sized thickness of construction steel (30 mm).

- Cutting of high-strength construction steel with lower heat input.

- High cutting speeds (up to 10 times higher than autogenous).

- Any processing of high-quality cut in medium size and thick sheet metal with turbulent gas technology in conjunction with technical gases.

- Very good automation.

- Plasma cutting under water for very small heat affecting of the material to be cut and low noise level around the workplace.

|

- Restriction of the use of up to 160 mm (180 mm) for dry cutting and 120 mm for cutting under water.

- A somewhat wider kerf.

|

|

Laser

|

- High precision of cut parts in small and medium thicknesses of materials.

- Cutting of very small holes, narrow strips, sharp-angled shapes, production of complex contour parts.

- Rectangular cutting edge.

- Very good automation.

- Very little amount of heat brought, no deformation of the machined object.

- A very small kerf width (0.2 – 0.4 mm).

- High speed cutting of thin materials.

|

- High investment and operating costs (high consumption of gas).

- Limits of the thickness of the material: Construction steel 20 (25) mm ; High-alloy steel 15 mm ; Aluminum 10 mm.

- For medium-thickness materials, no direct smooth cut surface.

- An accurate control of the distance to the workpiece surface is necessary.

- Limitation of beam stability in cutting of construction steels with normal Si and P content.

- Reducing of the cutting process stability of the shiny surface material.

- Lower effectiveness (CO2-laser max. 10%).

|

|

Water jet

|

- Cutting of metal, non-metal and composite materials; large materials and thicknesses.

- No metallurgical changes on the cutting surface, no heat input.

- The narrow kerf, vertical cutting, high dimensional stability of machined items, excellent cutting quality.

- Good Automation during the cutting.

- Depending on the type, also an operation of multiple cutting heads.

- Connection of air gap.

|

- High investment and operating costs (compared with plasma: operating expenses 1:5 up to 1:20 depending on the material and its thickness).

- The relatively low cutting speed of “hard” materials.

- Noisy and wet cutting.

- Impossibility of using for manual cutting and limited in 3-D dimensions.

|

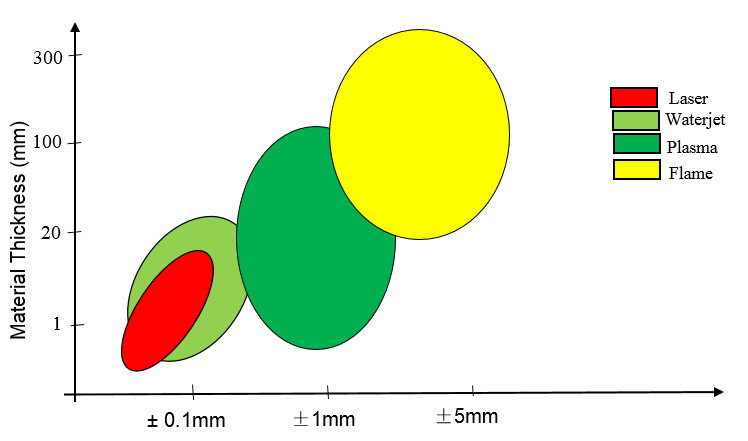

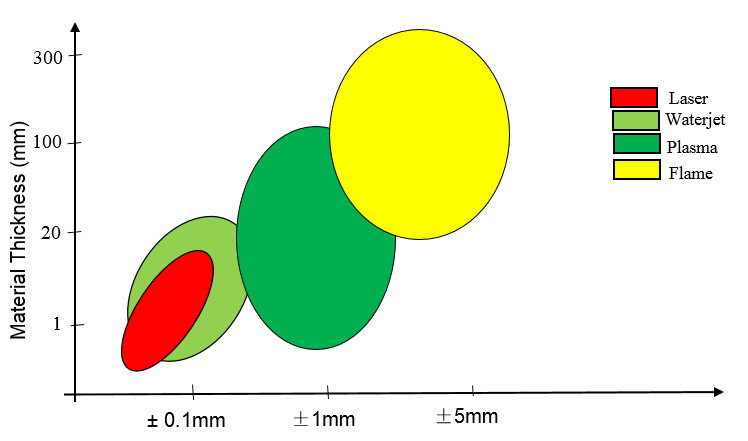

Comparison of methods: Flame – Laser – Water jet – Plasma

Possibilities of utilization of the cutting in the evaluation of quality, productivity and efficiency

(1 = best way, 4 = inappropriate way) |

| Requirement |

Tolerance |

Flame |

Laser |

Water jet |

Plasma |

| Construction steel< 5 mm |

up to ± 0,5 mm |

3 |

2 |

4 |

1 |

| Construction steel< 5 mm |

up to ± 0,1 mm |

no |

1 |

2 |

2 |

| Construction steel 5 – 20 mm |

up to ± 0,5 mm |

2 |

3 |

4 |

1 |

| Construction steel 5 – 15 mm |

up to ± 0,2 mm |

2 |

1 |

3 |

1 |

| Construction steel1 5 – 25 mm |

up to ± 0,5 mm |

2 |

3 |

3 |

1 |

| Construction steel 25 – 45 mm |

|

1 |

no |

3 |

1 (O2 ) |

| Construction steel> 45 mm |

|

1 |

no |

2 |

2 |

| High alloyed |

|

no |

yes |

yes |

yes |

| Aluminum |

|

no |

(yes) |

yes |

yes |

| Plastics |

|

no |

yes |

yes |

no |

Save