The Most Completed Operating Instructions of CNC Pipe Cutting Machine

Today ARCBRO will share the most completed using instructions of CNC pipe cutting machine. Hope everybody can operate it safely and efficiently.

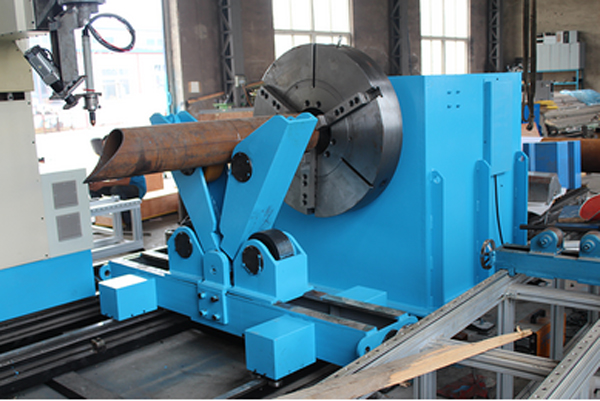

1, When the CNC pipe cutting machine is installed, turn on the power to check whether every part of the machine runs flexible, and whether the fasteners loose.

2, Press the button on the host to inspect if the rotation direction of the blade is consistent with the arrow’s. If the direction is reverse, adjust it immediately. Clamping pipe samples to be cut after the examination is completed. When do the clamping, you should choose a reliable clamping point to prevent false clamping and fake clamping. So as to avoid the cutter and pipe samples damage due to the pipe shifting during the cutting process.

3, When clamping irregular pipes, you can use the top-pressure method. Clamping steps: first put the pipe sample on the workbench, and then plug in the top-pressure moving clamp along the T-slot, set the distance between pipe sample and the clamp, lock the screw under the clamp base, move up and down the head bolt to choose a reliable clamping point, then lock head moving nut, rotate the top rod until it closely against the pipe sample, tighten the head moving nut to prevent the loose of the top rod in the cutting process.

4, When cutting core samples, if there are too many pipes, you can improve efficiency by pressing the long plate attached on some pipe samples to cut together. The clamping steps are as follows: put the pipe sample on the workbench, insert the press plate bolt along the T-slot, one end of the long plate inserts into the hole in the vertical surface of the workbench, turn the adjusting screw and the nut on the press plate bolt, compact the pipe samples tightly. If there is slight error in the diameter of the core samples, you can add a thin board the pipe sample to get the press plate bolt press the sample.

5, When we start to cut a pipe, we should start the motor first, and then press the start button. Adjust the feeding speed according to the hardness of the pipe before working. For it is possible to occur cutting marks if you adjust the speed during the cutting process.