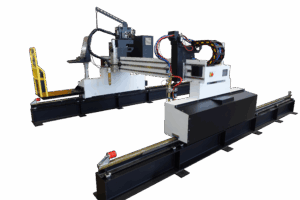

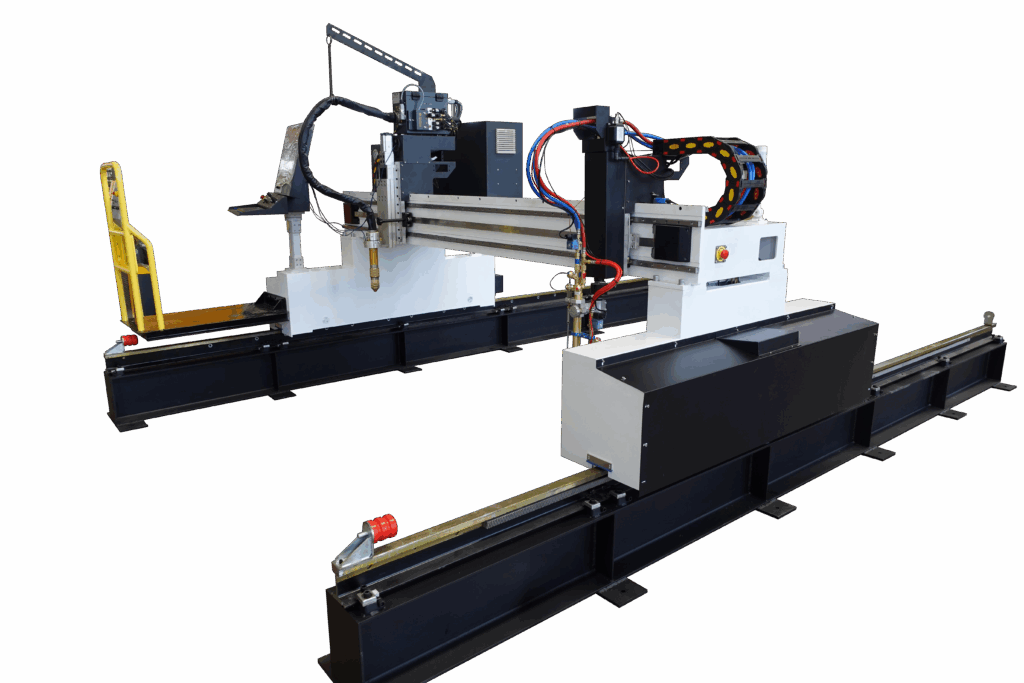

X Master HEAEY DUTY HD PLASMA CNC GANTRY CUTTING MACHINE

Cutting function: High definition plasma cutting

Cutting Size: 3000x12000mm

Cutting Tolerance: Within iso range 3

High definition plasma cutting is a new technology that has been around for less than a year. It is completely different from traditional plasma cutting.

Experts in the cutting industry know that plasma cutting quality is affected by six factors: current, gas, Pierce technology, led in/out technology, cutting speed, timing. These six factors are independent of each other in traditional cutting. Only experienced and skilled workers can combine them and complete a high-quality cutting.

No matter how skilled the craftsman of a craftsman is, due to the shape of the plasma flame itself, there is always a taper in the small hole. The upper and lower edges of the metal have different apertures, which necessitates that the holes must be cut to fit into the bolts. Small holes and bolts are the most widely used plasma cutting applications.

- SPECS

- DATA SHEETS

| Cutting mode | high definition plasma cutting for true hole technology |

| Effective cutting area | Width 2.5- 5m Length minimum 6m (Length and width can be optional |

| Number of torches | a set of automatic plasmas, a set of automatic flames |

| Drive mode | Longitudinal – 1000Wx2 large inertia; horizontal – 750Wx1 large inertia; lifting 400 W; Japan Panasonic servo system, dual drive mode |

| Reducer | 1:40 Nidec |

| Vertical orbit | Silver 38 kg rail on the longitudinal rail; silver (silver) 20 linear rail in the horizontal direction; |

| Rack and pinion specifications | 2-mode helical tooth |

| Cutting thickness | 0 – 45 mm perforation cutting (plasma); flame cutting thickness 0-200mm (for thicker optional |

| Small hole technology nesting software | Sigma nesting / lantek / pronest |

| Running speed | 0-15000mm/min |

| positioning accuracy | ±0.08 mm |

| Tolerance | ≤0.3mm |

| Machine input voltage | 220V single phase |

X MASTER

STILL HAVE QUESTIONS? CONTACT US NOW!

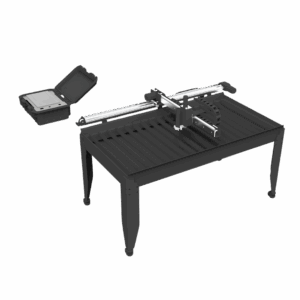

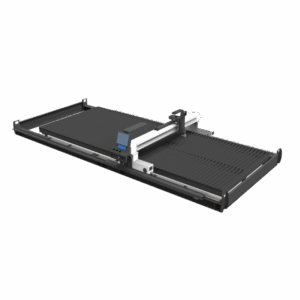

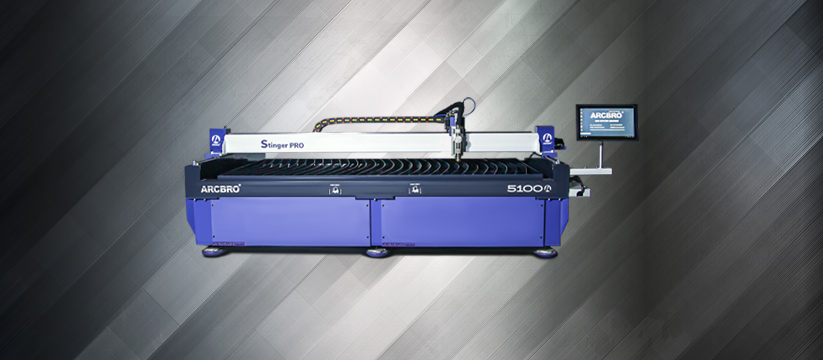

CHOOSE A PRODUCTS

Choose the one that best meets you in all range of ArcBro professional CNC cutter!

LEARNING CAMPUS

View ARCBRO learn campus online to learn the machines before you get them.