Tube-S

CNC PLASMA TUBE CUTTING MACHINE

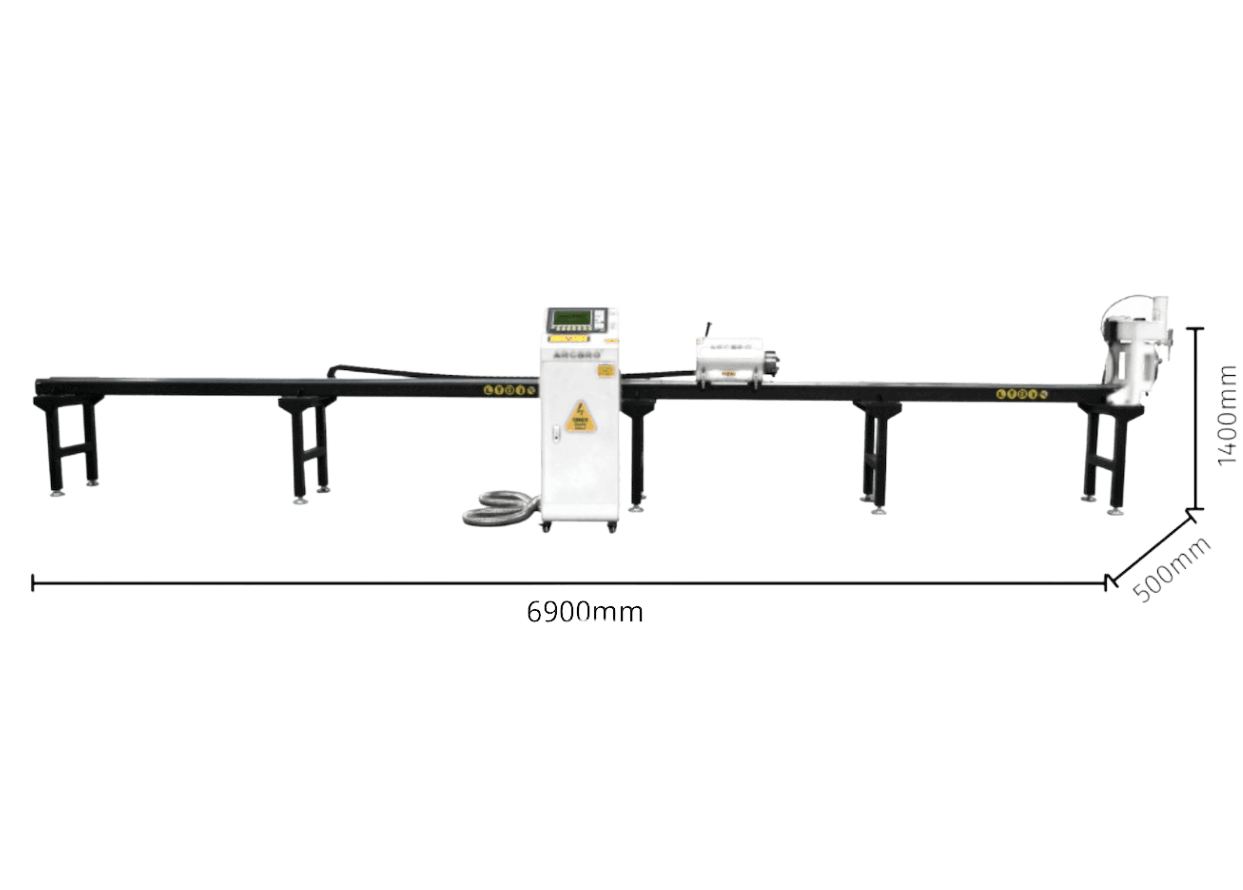

- Effective cutting size: φ30-120mm, 3000-6000mm long

- Two axis

- Fangling F2300A system

- HYD PTHC-200DC-PT

- Standard three-jaw chuck + three-jaw welding chuck

- Panasonic servo motor

FOCUS ON THE PRODUCTION EFFICIENCY AND

PRECISION OF METAL PIPE CUTTING.

Tube-S is designed for small pipe works, which is a good choice for many different working fields.

Such as CAR MANUFACTURES, PRODUCTION FRAME, STREET FACILITIES, and STREET LIGHTS, and also FIRE PIPE WORKS in the building.

To compare with the traditional cutting method, Tube-S is a true production machine.

DISCUSS ALL AVAILABLE OPTIONS TO ACHIEVE YOUR GOAL !

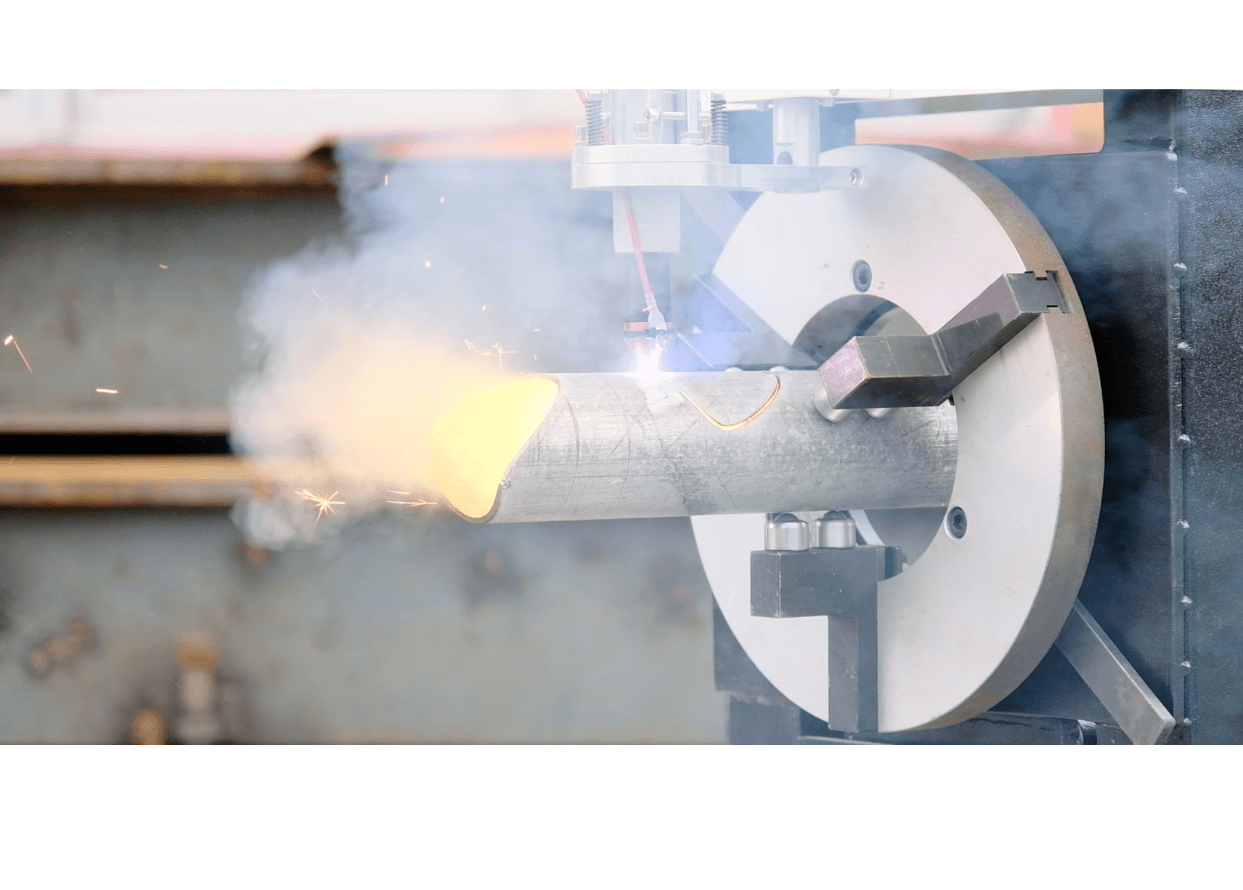

To extreme the product efficiency. Tube-S is designed for high-speed running and rotation. It can be 12000mm/min. The Tube-S adopts a double chuck design to ensures that the tube will not jump during that so fast cutting process, Minimize vibration.

Tube-S can cut intersecting lines on the surface of the tube for seamless welding in the next step. Reduce the time and cost of secondary processing.

Low Shipping & Simple Installation. Tube-S only separates the legs when packaging, which reduces the height of the body by half, which in turn saves half of the transportation volume and cost. Install the table legs with screws, plug in the power and start working! This CNC Plasma Tube cutting machine is also Plug & play!

- SPECS

- DATA SHEETS

| Type | Tube-S |

| Input Power | 110V / 220V, °1Ph / 60Hz |

| Traverse Speed | 0 - 8000mm / min |

| Pipe Capacity | 25 - 120 mm |

| Height Control | HYD Arc Voltage THC |

| Travel - Longitudinal | 3 m / 6 m |

| Maximum Cutting Speed | 0 - 8000mm / min |

| Pipe Rotation Drive | Precision planetary gear box and belt drive |

| Linear Motion | Precision rack and pinion |

| Cutting Process | Plasma |

| Temperature | 40-100°F (1-38°C) |

| Language | English, Chinese, Spanish, Russian, French, Japanese, Czech, and Slovenia, etc. |

| Fume Extraction | Custom quotes are available upon request |

ARTILLERY

Pipe OD: 50*50 to 400*400 mm

CNC Square Pipe

Standard Length: 16 m

Length can be costomized

ArcBro’s Community is a very DYNAMIC and FREE communication community which is composed of Metal Workers with many years experiences, professional cutting ENGINEERS, and ArcBro’s LOYAL CUSTOMERS.

You can feel free to communicate and discuss all issues about all cutting questions and problems, learn more cutting tips. The engineer team will reply all the time!

STILL HAVE QUESTIONS? CONTACT US NOW!

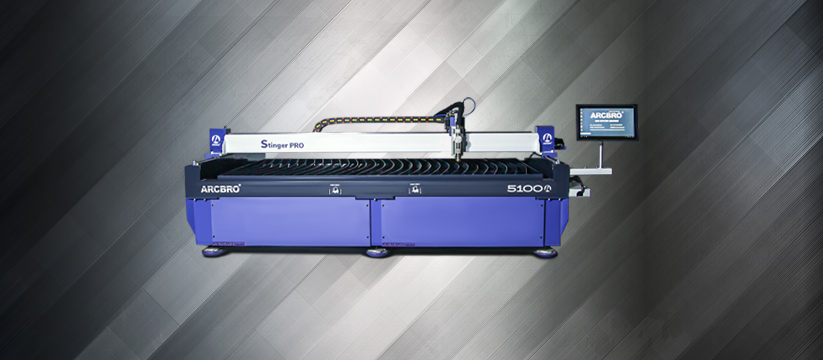

CHOOSE A PRODUCTS

Choose the one that best meets you in all range of ArcBro professional CNC cutter!

LEARNING CAMPUS

View ARCBRO learn campus online to learn the machines before you get them.