AKSON

Laser Welding & Cleaning AIO Machine

Overview

- Laser welding is a kind of processing method which uses high energy density laser beam as heat source to weld materials.

- In recent years, due to the continuous development and progress of materials, technology and process, laser has been widely used in the welding and brazing of plastics, metals, etc., and will continue to replace the traditional welding methods such as argon arc welding in automobile, sensor, electronic and other industries.

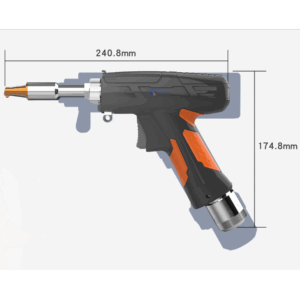

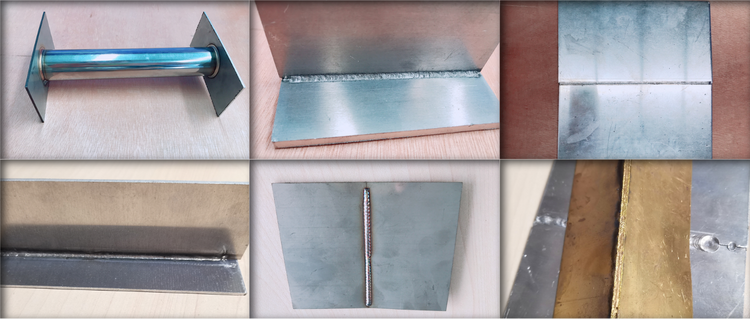

- Hand held laser welding machine with hand-held welding head, similar to argon arc welding, flexible and simple operation, suitable for small batch and large batch orders with low requirements for product consistency

- It can be widely used in the complicated and irregular welding process of cabinet, kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home and other industries.

Advantage

- Laser welding is a kind of processing method which uses high energy density laser beam as heat source to weld materials.

- In recent years, due to the continuous development and progress of materials, technology and process, laser has been widely used in the welding and brazing of plastics, metals, etc., and will continue to replace the traditional welding methods such as argon arc welding in automobile, sensor, electronic and other industries.

- Hand held laser welding machine with hand-held welding head, similar to argon arc welding, flexible and simple operation, suitable for small batch and large batch orders with low requirements for product consistency

- It can be widely used in the complicated and irregular welding process of cabinet, kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home and other industries.

Superior Machinery, every set is

heat treated processed

!

COMPARISON:LASER WELDING / TRADITIONAL WELDING

| COMPARISON ITEMS | TRADITIONAL WELDING | LASER WELDING |

| Heat input to work-piece | Very high | Low |

| Deformation and undercut of work-piece | Large | Small |

| Bond strength with base metal | Commonly | Very Nice |

| Follow up treatment | Polish | No grinding, or little grinding |

| Welding Speed | Commonly | More than 2 times of argon arc welding |

| Applicable materials | Stainless steel, carbon steel, galvanized sheet | Stainless steel, carbon steel, galvanized sheet |

| Consumables | Many consumables | Less consumables |

| Operation difficulty | Complex | Simple |

| Operator safety | Unsafe | Safe |

| Environmental impact | Not environmental | Environmental |

| Welding fault tolerance | Good | Good |

| Swing welding | – | Yes |

| The spot width is adjustable | – | Yes |

| Welding quality comparison | Bad | Very good |

TECHNICAL INFO

- SPECS

- DATA SHEETS

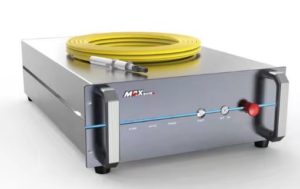

Product Type | Laser Welding | ||

Model | Akson-1500 | Akson-2000 | Akson-3000 |

Laser power | 1500W | 2000W | 3000W |

Working voltage | 220V/380V | ||

Laser wavelength | 1070±20 | 1080nm | 1080nm |

Conduction type | Fiber laser | ||

Welding speed range | 0~120mm/s | ||

Water chiller | Industrial constant temperature water tank | ||

Working environment temperature range | 10 〜40°C | ||

Humidity range of working environment | <70% No condensation | ||

Welding ability | Stainless steel 6mm/Carbon steel 6mm/Aluminum 4mm | ||

Welding seam requirements | ≤0.5mm | ||

Machine size(mm) | 860*390*620 | 1050*480*845 | 1213*606*1239 |

Weight(kg) | 80 | 85 | 110 |

Plasma Power Source Recommendation

STILL HAVE QUESTIONS? CONTACT US NOW!

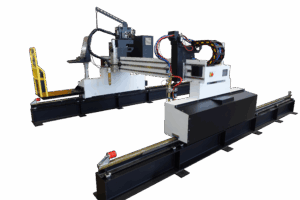

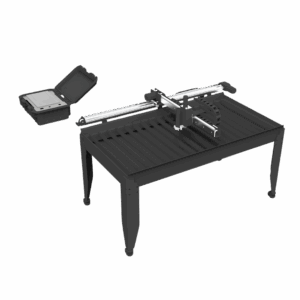

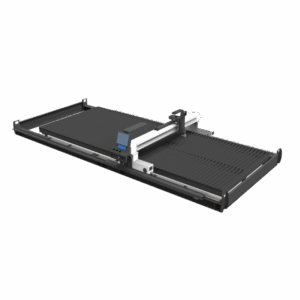

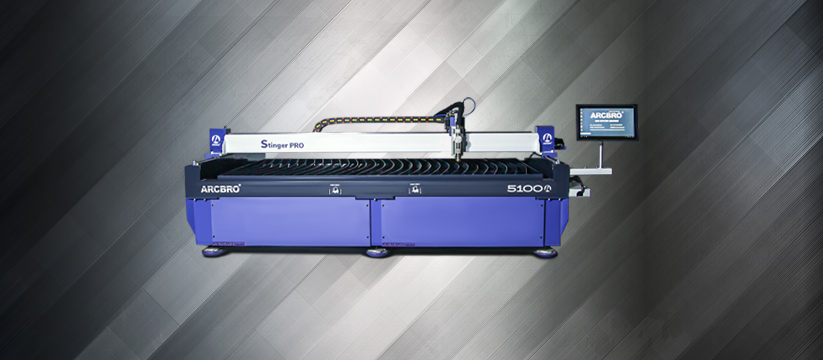

CHOOSE A PRODUCTS

Choose the one that best meets you in all range of ArcBro professional CNC cutter!

LEARNING CAMPUS

View ARCBRO learn campus online to learn the machines before you get them.