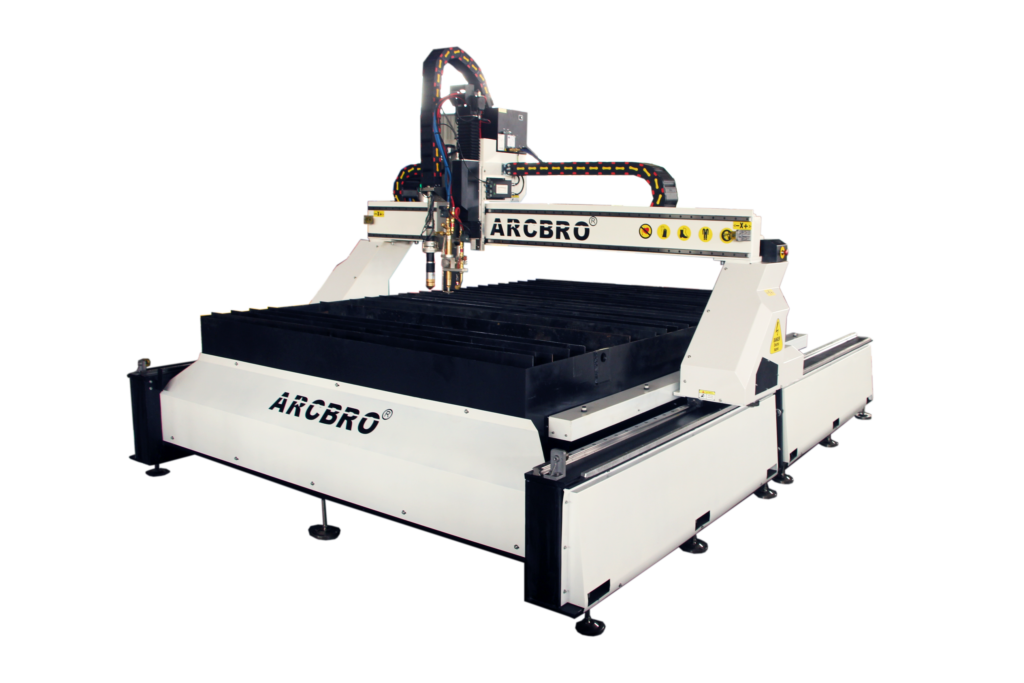

The heavy duty plasma cutting table – X Mark, available exclusively from ArcBro, challenges the concept of the traditional plasma cutting industry: high productivity, high cutting quality, precise cuts at fast speeds reduce secondary operations and streamline your manufacturing processes, which in turn reduces costs and increases production, built-in integrated cutting process, the perfect round hole for one-button cutting, and reliance on worker skills.

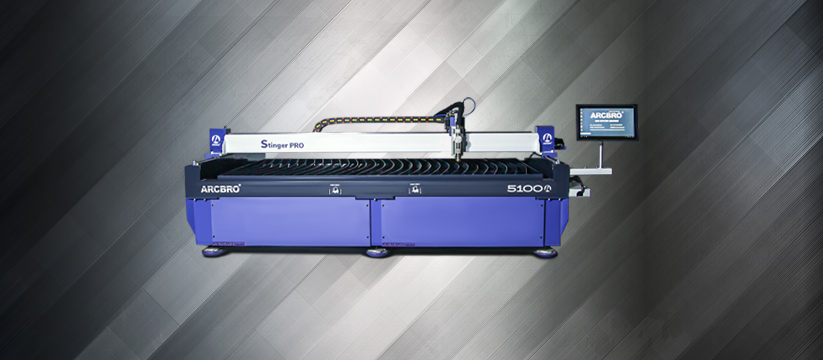

The new process is called high definition plasma cut, which is a leap in every aspect in plasma.